We Have The Best Solutions for Your Business

Kason Technology Co., Ltd. was established in 2010, and is a subsidiary of Guangdong Yixinfeng Intelligent Equipment Co., Ltd. We are a national high-tech enterprise that specializes in the front-end and back-end production of new energy lithium battery cells integrating technology R&D, manufacturing and sales services, as well as related precision CNC machining.

Our main products are Electrode Making Machine, High Speed Slitting Machine, High Speed Die Cutting Machine, Electrode Making Equipment, Electrode Cutting Machine, Lithium Battery Equipment, Lithium-ion Cell Manufacturing, Battery Fabrication Equipment, Laser Die Cutting Machine, Lithium Ion Battery Machine, Lithium Battery Machine, Cells Making Machine, Pouch Cell Manufacturing, Battery Lamination, Cell Stacking Machine, Pouch Battery Assembly, Hard Pack Battery Making Machine, Hard Pack Battery Production Equipment, etc

Lithium-ion battery production process

In the production process of lithium-ion batteries, the production of pole pieces is the basis, the production of cells is the core, and battery assembly is related to the quality of the finished lithium-ion battery. The specific links of the lithium-ion battery production process include positive electrode slurry, negative electrode slurry, positive electrode sheet, negative electrode sheet, steel shell assembly, liquid injection and testing, and packaging.

Frequently Asked Question

Do you have any question?

Battery manufacturing encompasses the production of modular electric power sources where part or all of the fuel is contained within the unit and electric power is generated directly from a chemical reaction.

Some specific machines associated with battery assemblers are cell winders and tab welders. Cell winders are capable of winding round or prismatic cells 3-12 parts per minute. It is flexible enough to handle up to 5 tabs per cell at varied distances.

Welding and building a BMS is the first step. Second stage involves import of rolls of Cathode, Anode, Separator and make cells and assemble them into batteries. In the third stage, coating of Cathode and Anode can be taken up.

Our updates and blog posts

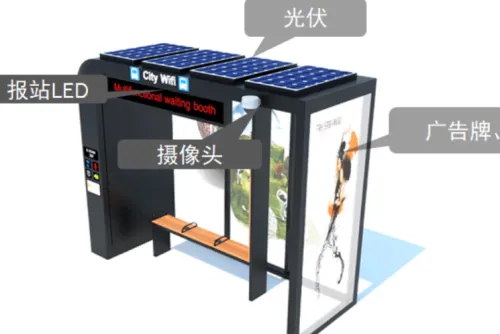

cells-making-machine |Photovoltaic Energy Storage: The Most Popular New Application Model

{keyword}.In recent years, the cost of PV energy storage system has been gradually reduced, and the technology has been optimized, so PV & storage has been rapidly developed and highly valued under such a general environment.

cells-making-machine | Introduction Of Household Energy Storage Systems

{keyword}, Hybrid photovoltaic + energy storage systems generally consist of photovoltaic modules, lithium batteries, hybrid inverters, smart voltmeters,

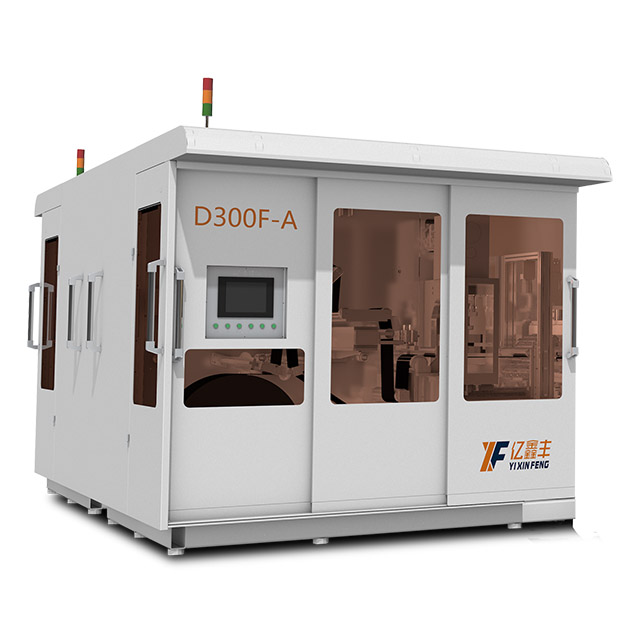

cells-making-machine | The Working Principle Of Lithium Battery Automatic Die-cutting Machine

{keyword},he machine is mainly used for cathode and anode oxidation of lithium cell and Z-shape winding installation of protective film